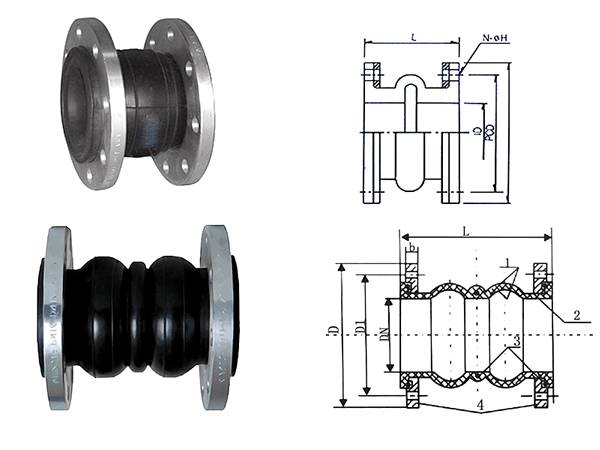

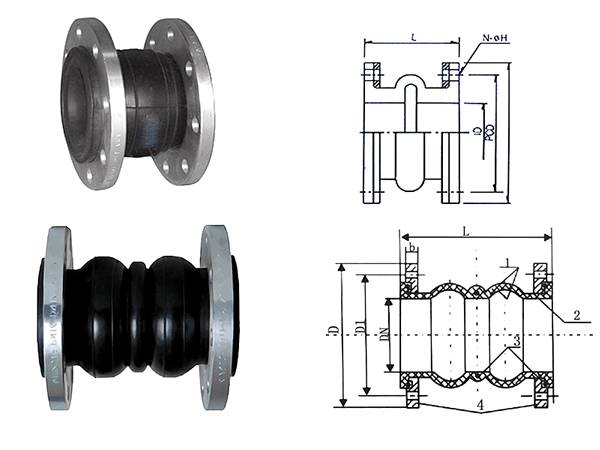

Types and drawings of rubber flexible joint.

Need Help? E-mail: tina@hebeiqianli.com

Qianli has been producing with the latest processing machines. Let's take a look at the products with us.

Read More

Rubber flexible joint is lightweight but versatile.

Rubber flexible joints, also called rubber elastomer joints, is constructed of neoprene and nylon with internal and stainless steel rings external structures.

It can provide superior performance in absorbing movement and reducing mechanical noise, reliability and long service life. All result in improved plant safety and increased mechanical integrity of equipment.

The rubber flexible expansion joints are inserted in a rigid piping system for following functions:

Structures of rubber flexible joint

Types and drawings of rubber flexible joint.

| Nominal Diameter | Length | Flange Thickness | Bolt No. | Bolt Diameter | Bolt Circle Diameter (D1) | Axial Movement | Lateral Movement | Deflection Angle | ||

| Extension | Compression | |||||||||

| mm | inch | mm | mm | n | mm | mm | mm | mm | mm | a1 + a2 |

| 32 | 1.25 | 95 | 16 | 4 | 18 | 100 | 6 | 9 | 9 | – |

| 40 | 1.5 | 95 | 18 | 4 | 18 | 110 | 6 | 10 | 9 | 15 |

| 50 | 2 | 105 | 18 | 4 | 18 | 125 | 7 | 10 | 10 | 15 |

| 65 | 2.5 | 115 | 20 | 4 | 18 | 145 | 7 | 13 | 11 | 15 |

| 80 | 3 | 135 | 20 | 4 | 18 | 160 | 8 | 15 | 12 | 15 |

| 100 | 4 | 150 | 22 | 8 | 18 | 180 | 10 | 19 | 13 | 15 |

| 125 | 5 | 165 | 24 | 8 | 18 | 210 | 12 | 19 | 13 | 15 |

| 150 | 6 | 180 | 24 | 8 | 23 | 240 | 12 | 20 | 14 | 15 |

| 200 | 8 | 210 | 24 | 8 | 23 | 295 | 16 | 25 | 22 | 15 |

| 250 | 10 | 230 | 26 | 12 | 23 | 350 | 16 | 25 | 22 | 15 |

| 300 | 12 | 245 | 28 | 12 | 23 | 400 | 16 | 25 | 22 | 15 |

| 350 | 14 | 255 | 28 | 16 | 23 | 460 | 16 | 25 | 22 | 15 |

| 400 | 16 | 255 | 30 | 16 | 25 | 515 | 16 | 25 | 22 | 15 |

| 450 | 18 | 255 | 30 | 20 | 25 | 565 | 16 | 25 | 22 | 15 |

| 500 | 20 | 255 | 32 | 20 | 25 | 620 | 6 | 25 | 22 | 15 |

| 600 | 24 | 260 | 36 | 20 | 30 | 725 | 6 | 25 | 22 | 15 |

| 700 | 28 | 260 | 36 | 24 | 30 | 840 | 16 | 25 | 22 | 15 |

| 800 | 32 | 260 | 38 | 24 | 34 | 950 | 16 | 25 | 22 | 15 |

| 900 | 36 | 260 | 42 | 28 | 34 | 1050 | 6 | 25 | 22 | 15 |

| 1000 | 40 | 260 | 44 | 28 | 34 | 1160 | 18 | 26 | 24 | 15 |

| 1200 | 48 | 260 | 48 | 32 | 41 | 1380 | 18 | 26 | 24 | 15 |

| 1400 | 56 | 350 | 44 | 36 | 34 | 1560 | 20 | 28 | 26 | 15 |

| 1600 | 64 | 350 | 46 | 40 | 34 | 1760 | 25 | 35 | 30 | 10 |

| 1800 | 72 | 350 | 52 | 44 | 41 | 1970 | 25 | 35 | 30 | 10 |

| 2000 | 80 | 420 | 54 | 48 | 48 | 2180 | 25 | 35 | 30 | 10 |

| 2200 | 88 | 400 | 40 | 52 | 48 | 2390 | 25 | 35 | 30 | 10 |

| 2400 | 96 | 400 | 41 | 56 | 48 | 2600 | 25 | 35 | 30 | 10 |

| 2600 | 104 | 450 | 42 | 60 | 54 | 2810 | 25 | 35 | 30 | 10 |

| 2800 | 112 | 450 | 45 | 64 | 54 | 3020 | 25 | 35 | 30 | 10 |

| 3000 | 120 | 450 | 50 | 68 | 54 | 3220 | 25 | 35 | 30 | 1 |

Features

Applications

Wide range of applications.

Because the rubber joint has good comprehensive properties, so it is widely used in:

Contact Form

You have a specific question or would you simply like to learn more about us?

Find our contact information below or use our Contact Form.